Integrating the appropriate industrial dust collector fan into your system is essential for optimal performance. The primary choices include radial blade fans, backward inclined (BI) fans, backward curved (BC) fans, and airfoil fans, each designed to meet different operational needs.

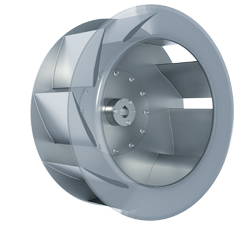

Radial Blade Fan

The dust collector fan blade in radial fans is perpendicular to the wheel’s rotation, resembling a paddle wheel design. These fans, ideal for material handling and high-pressure applications, are known for their durability but are generally less efficient, making them the least efficient option among centrifugal fans for dust collectors.

Backward Inclined Fan

For industrial settings prioritizing efficiency and value, the backward inclined fan stands out. Its flat blades, leaning away from the rotation direction, offer better efficiency compared to the radial blade fan, with a horsepower curve designed to prevent overloading, enhancing the dust collector blower fan performance.

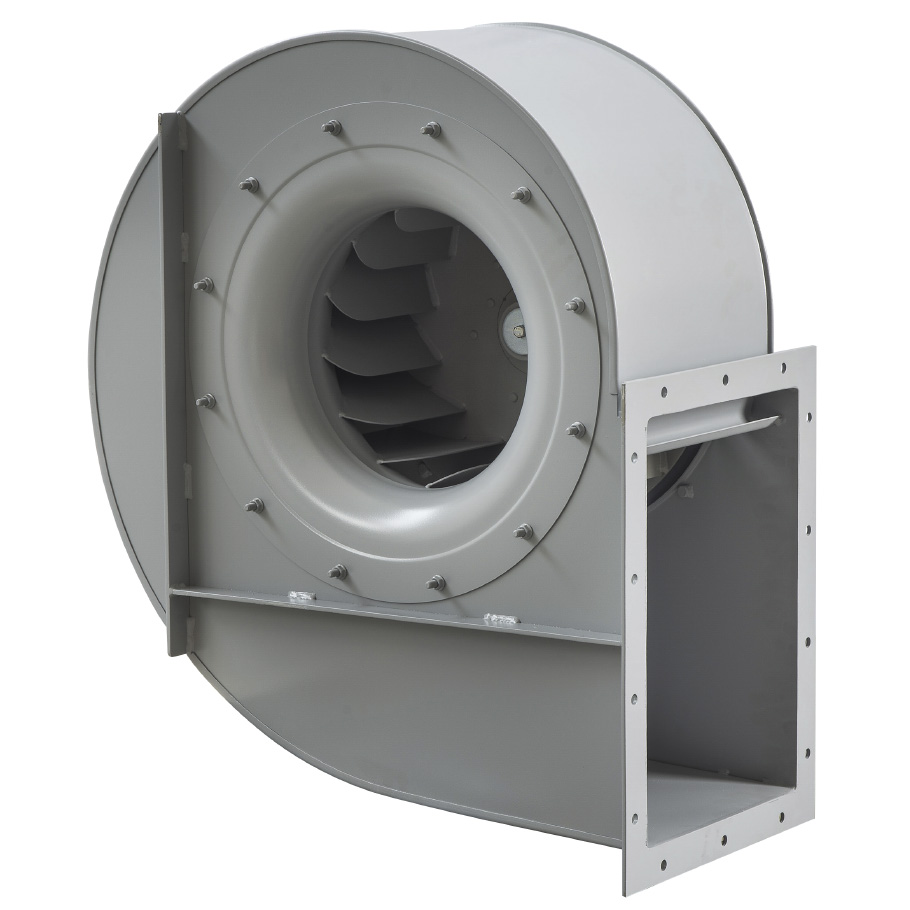

Backward Curved Fan

The backward curved fan operates more quietly and efficiently than its BI counterpart, capable of generating higher pressures with its slightly curved blades. This fan’s non-overloading horsepower curve makes it a robust choice for dust collector exhaust fans in more demanding environments.

Read this similar kind of blog: CENTRIFUGAL FANS VS AXIAL FANS: UNDERSTANDING THE DIFFERENCES AND EFFICIENCY

Airfoil Fan

As the most efficient and quietest option, the airfoil fan is preferred for energy-saving industrial applications. Its unique hollow-blade design, suitable for clean air applications, and non-overloading curve, underscore its superiority as an industrial dust collector fan.

For more information write to us at sales@atmaxfiltration.com or call us at +1 (816)-745-9994