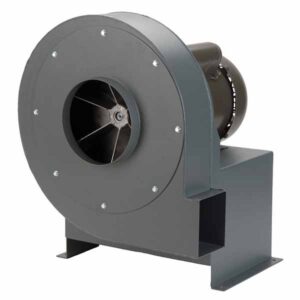

Industrial Dust collectors are an essential tool for many industries, including woodworking, metalworking, and agriculture. For the majority of dust collection applications, industrial fans are crucial elements. Dust collector fans either push or pull air through the system.

A dust collector fan creates the necessary suction to draw dust and particles into the collector. The size of the fan dictates the amount of air volume of the Dust Collector System. Improper sizing cannot produce the desired air volume and puts unnecessary pressure on the system. Inturn leading to frequent maintenance and low efficiency.

There are 5 important considerations to keep in mind when sizing for an industrial dust collector fan.

5 Tips to Choose a Right Dust Collector Fan

Air Flow Requirements

First, it’s important to determine your airflow and pressure requirements. Airflow is measured in cubic feet per minute (CFM), while pressure is measured in inches of water gauge (in. w.g.). The CFM indicates the volume of air that the fan can move, while the in. w.g. measures the resistance that the air encounters as it passes through the ductwork and filters. Proper dust collector fan sizing is critical to ensure that the fan can deliver the required CFM at the required pressure.

Static Pressure of Fan

Static pressure is an important consideration when selecting a dust collector fan. It refers to the resistance that the air encounters as it passes through the ductwork and filters. Proper dust collector fan sizing is critical to ensure that the fan can deliver the required CFM at the required pressure. The fan’s ability to handle high-pressure drops is critical to its performance in most applications. Therefore, it’s important to consider the static pressure requirements of your dust collection system when selecting a fan to ensure optimal performance and efficiency.

Dust Collector Fan Sizing

Once you have determined your airflow and pressure requirements and selected the right fan type, it’s important to consider the fan size. The size of the fan you need will depend on the CFM and pressure requirements of your system. Proper dust collector fan sizing ensures that the fan provides enough suction to draw dust and particles into the collector, without consuming more energy than necessary.

Efficiency and Noise Level of Fan

Efficiency and noise level are also important considerations when selecting a dust extractor fan or dust collector blower fan. An efficient fan will consume less energy, saving you money on electricity costs. The fan’s efficiency is measured by its static efficiency, which is the ratio of the fan’s actual power consumption to its ideal power consumption. Noise level is also important, especially if you will be using the fan in a small or enclosed space. Fans generate noise as they move air, and this noise can be a distraction or even a safety hazard in some cases. Look for fans that are designed to be quiet, and check the manufacturer’s specifications for the fan’s noise level. These five tips will ensure that your dust collector is running smoothly.

Choose a Right Supplier or Manufacturer

Finally, it’s important to choose a reputable manufacturer for your dust collector fan blade or blower fan. The fan should be compatible with the ductwork, filters, and other components of your system to ensure optimal performance and safety. Using an incompatible fan can cause performance issues, damage to the system, and potentially compromise worker safety.

In summary, selecting the right dust collector fan requires careful consideration of airflow and pressure requirements, fan type, size, efficiency, and noise level. It’s also important to choose a reputable dust collector manufacturer and ensure compatibility with your system. With the right dust collector blower or extractor fan in place, you can protect the health and safety of your workers while keeping your work environment clean and free from harmful dust and particles.

What type of fan is generally used for a dust collector?

When it comes to selecting the right fan for a dust collector, there are four main types of fans to consider:

Radial blade

Backward curved

Backward Inclined,

Airfoil

Each type of fan has its own unique characteristics that make it more suitable for certain applications than others. Here is a brief description of each type of fan:

Radial blade fans

It is also known as paddle-wheel fans – are the simplest type of fan and consist of a wheel with flat blades. They are low-cost, low-maintenance fans that can handle high static pressure drops. However, they are not as efficient as other types of fans and can be quite noisy.

Backward curved fans

These are more efficient and quieter than radial blade fans. They have a curved blade that is tilted away from the direction of the airflow, which allows the fan to move air more efficiently with less energy. They can also handle high static pressure drops, making them suitable for many dust collection applications.

Backward inclined fans

They have a blade that is tilted in the opposite direction of the airflow. They are highly efficient and produce less noise than other types of fans. However, they are not as good at handling high static pressure drops as radial blade and backward curved fans.

Airfoil fans

These are the most efficient type of fan and are often used in large-scale industrial applications. They have a curved blade that is shaped like an airplane wing, which allows the fan to move air with a high level of efficiency. They are also quieter than other types of fans and can handle high static pressure drops.

If you need help sizing your fan, you can contact one of our equipment specialists at Atmax Filtration