Maintaining high food safety standards is crucial in the food and beverage industry. Proper equipment selection, including food-grade hoses, plays a vital role in preventing product contamination. In the United States, food-grade hoses must adhere to strict guidelines set by the Food and Drug Administration (FDA). This blog post will delve into the essential characteristics and applications of food-grade hoses, with a focus on Atmax Filtration Elements Inc.’s expertise in providing reliable solutions for the food industry.

Key Characteristics of Food-Grade Hoses

Compliance with FDA and NSF Standards

Food-grade hoses, such as those offered by Atmax, are designed and manufactured to meet FDA and NSF requirements. This certification ensures that the hoses are safe for contact with food and maintain the integrity of food materials during transfer.

Non-Toxic and Corrosion-Resistant Construction

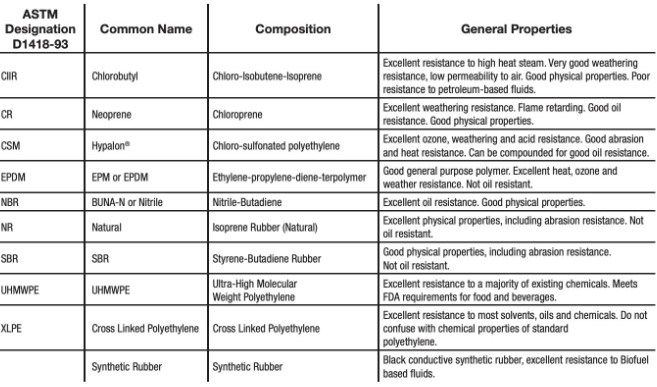

Our food-grade hoses are crafted from non-toxic materials, such as polyurethane, polyvinyl chloride (PVC), or thermoplastic rubber. These materials are resistant to corrosion, preventing contamination and ensuring product safety.

Durability and Strength

Our food-grade hoses are built to withstand the demanding conditions of food processing facilities. They exhibit excellent durability, allowing them to endure high temperatures, pressures, and rigorous usage without compromising performance.

Pressure and Vacuum Capabilities

Our food-grade hoses are designed to maintain specific pressure and vacuum levels required in various food processing operations. Our hoses offer reliable pressure capacities, ensuring optimal performance in different applications.

Odorless and Tasteless Design

Our food-grade hoses are engineered to be odorless and tasteless, preventing any undesirable flavors or odors from transferring to the food materials. This feature preserves the quality and integrity of the final products.

Typical Applications of Food-Grade Hoses

Bulk Dry Food Handling

Food-grade hoses are commonly used to transport bulk dry food materials, including cereals, flours, and sugars. Our food-grade hoses provide a safe and efficient means of conveying these products, meeting FDA standards and ensuring product integrity.

Pharmaceutical Production

In pharmaceutical manufacturing, food-grade hoses are employed to transfer capsules and tablets. Our FDA-compliant hoses meet the stringent requirements of pharmaceutical applications, maintaining the hygiene and quality standards necessary in the industry.

Other Food Processing Industries

Our food-grade hoses find applications in various food processing sectors, including cosmetic, spice, and sugar manufacturing. The hoses offer reliable performance, durability, and compliance with food safety regulations in these diverse applications.

Selecting the correct hoses is crucial to ensure food safety and prevent contamination in the food and beverage industry. Compliance with FDA and NSF standards guarantees the hoses’ integrity and suitability for contact with food materials. Atmax’s expertise in providing high-quality food-grade hoses ensures that food processing operations can rely on durable, compliant, and efficient solutions.

Remember to consult with our reputable Atmax Expert to ensure you choose the appropriate food-grade hoses for your specific application needs. By prioritizing food safety and using certified hoses, you can uphold the highest standards of quality and safeguard consumer well-being. Schedule your free consultation today!

You can further read about the Importance of Anti-Static Hoses at Importance of Anti Static Hoses

Citations:

Food and Drug Administration (FDA): [https://www.fda.gov/]

National Sanitation Foundation (NSF): [https://www.nsf.org/]