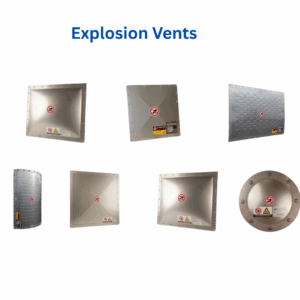

Explosion Venting

Explosion vents are designed to relieve pressure from a deflagration event by opening at a predetermined burst pressure. Because it activates solely from the pressure generated during an explosion, it eliminates the need for complex electronic detection or control systems, making it a cost-effective and reliable solution.

Explosion vent panels can be easily installed on a wide range of industrial equipment, from dust collectors to silos and process vessels. Their low-maintenance design and straightforward setup make them ideal for facilities looking to improve safety without the added complexity or cost of active suppression systems.

Why is Explosion Protection Important?

Many manufacturing processes generate fine dust particles that can become airborne and settle on equipment, floors, and other surfaces. If this dust is combustible, it poses a serious fire and explosion hazard especially when dispersed into the air, forming a potentially explosive dust cloud.

Combustible dust is a critical safety concern across various industries, including:

Agriculture

Chemical processing

Food and grain handling

Plastics and rubber manufacturing

Woodworking and textiles

Metal fabrication and finishing

Pharmaceutical production

To mitigate the risk of fire or explosion, facilities must implement proper dust collection, housekeeping, and explosion protection systems.

Local, state, and federal safety regulations apply to facilities handling combustible dust. Many of these regulations reference standards from the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA), such as NFPA 652, NFPA 68, and NFPA 69, which guide hazard identification, risk assessment, and the implementation of explosion prevention or venting systems

Flameless Explosion Vents

Flameless explosion vents are designed to safely relieve pressure from a dust or gas explosion without allowing flames or hot gases to escape into the workspace. They combine traditional venting with a flame arrestor mesh that extinguishes the flame front, making them ideal for indoor applications or equipment installed in occupied areas. This helps protect both personnel and facility infrastructure.

Isolation Valves

Isolation valves act as a barrier that prevents the propagation of explosion pressure or flame from one part of a system to another. Installed on ducts or piping, they automatically close during an explosion event, protecting upstream equipment like silos, dust collectors, or process vessels. These valves are essential for compartmentalizing explosion hazards and preventing secondary explosions.

Fire Suppression Systems

Fire suppression systems detect and extinguish fires or explosions before they escalate. These systems can be chemical-based or water mist-based, and they are activated either manually or automatically upon detecting flame, heat, or pressure rise. Used in tandem with explosion vents or isolation devices, fire suppression enhances overall system safety, especially in environments where combustible dust, flammable gases, or vapors are present.

Cartridge Filters Download Brochure

We are one of a handful of companies designated by Donaldson Torit to bring to you only genuine filters and parts guaranteed to work with your system

Let’s Start Work Together

- 2101 Park Ave, South Plainfield NJ 07080, USA South Plainfield, United States, 7080

- sales@atmaxfiltration.com

- +1-816-745-9994

- Mon – Fri : 8:00 AM to 7:00 PM

Atmax Filtration provides high quality dust collectors and accessories and supplies in the entire New Jersey.

For more information talk to us on (816)-745-9994 or write at sales@atmaxfiltration.com

No posts found!