The semiconductor industry is one of the most demanding in terms of environmental control. Even the slightest variation in temperature, humidity, or air quality can compromise product quality, reduce yield, and increase operational costs. HVAC (Heating, Ventilation, and Air Conditioning) systems designed specifically for semiconductor manufacturing facilities are vital for maintaining the strict environmental conditions required for cleanrooms and production areas.

In this guide, we’ll explore the importance of specialized HVAC equipment in the semiconductor industry, key features to consider, and how advanced solutions can address the unique challenges faced by this sector.

Why Specialized HVAC Systems Are Crucial for Semiconductor Manufacturing

1. Stringent Environmental Requirements

Semiconductor manufacturing cleanrooms must adhere to ISO 14644 standards, which define permissible particle levels across various cleanliness classes. For instance, ISO Class 1 cleanrooms allow no more than 10 particles (0.1 microns or larger) per cubic meter. ISOA Class 5, often used in semiconductor manufacturing, permits up to 3,520 particles (0.5 microns or larger) per cubic meter. HVAC systems are critical in achieving and maintaining these stringent conditions. HVAC systems ensure:

- Temperature control within ±0.1°C.

- Humidity levels between 40-60% RH (Relative Humidity).

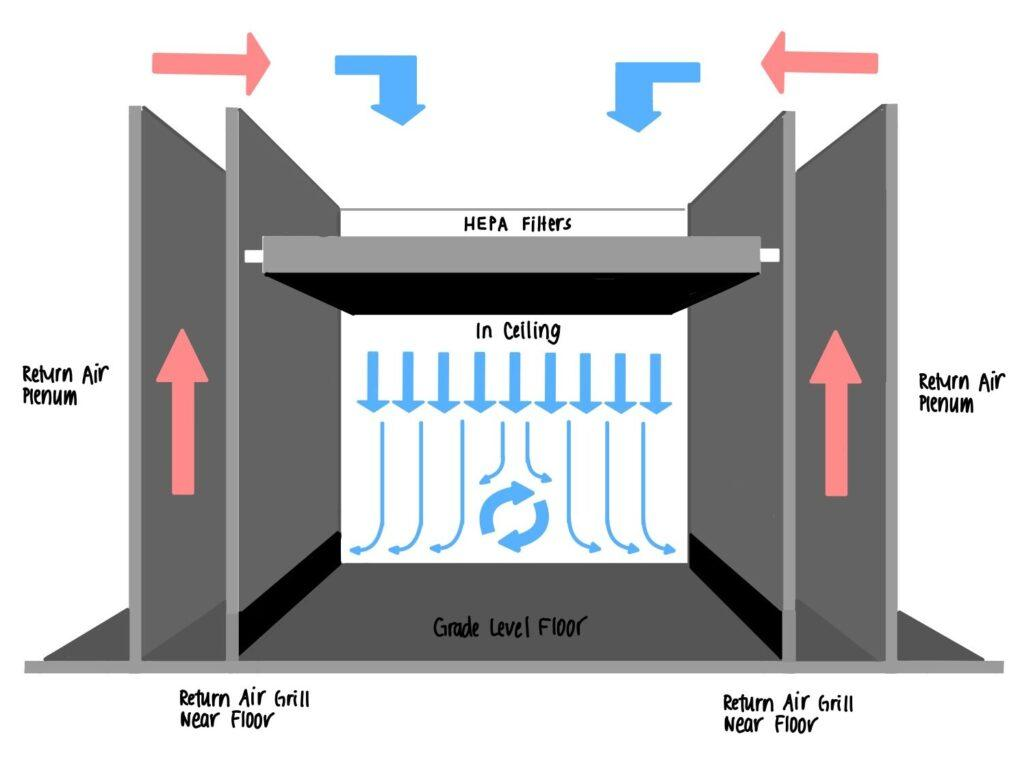

- Laminar airflow to minimize turbulence and particle generation.

2. Particle Control

HVAC systems equipped with High-Efficiency Particulate Air (HEPA) and Ultra-Low Penetration Air (ULPA) filters are critical for maintaining cleanroom standards in semiconductor manufacturing. HEPA filters capture 99.97% of particles as small as 0.3 microns, making them effective for most airborne contaminants. ULPA filters, on the other hand, can capture up to 99.999% of particles as small as 0.1 microns, offering an even higher level of protection. While HEPA filters are more commonly used, ULPA filters are ideal for processes requiring ultra-clean environments, ensuring the prevention of contamination in delicate semiconductor components.

3. Energy Efficiency

Semiconductor facilities operate 24/7, making energy efficiency a priority. Modern HVAC systems reduce energy consumption without compromising performance, aligning with sustainability goals.

4. Process Stability

Precise temperature and humidity control ensure stable conditions for photolithography, etching, and deposition processes, reducing defect rates and improving product yield.

Key Features of Semiconductor HVAC Equipment

1. Advanced Filtration Systems

- HEPA and ULPA Filters: Capture particles as small as 0.1 microns.

- Gas-Phase Filtration: Removes volatile organic compounds (VOCs) and chemical pollutants.

2. Humidity Control

- Use of desiccant dehumidifiers for precise humidity regulation.

- Integration of humidification systems to maintain optimal RH levels.

3. Temperature Precision

- Variable Air Volume (VAV) systems and Direct Digital Controls (DDC) ensure temperature consistency.

- Advanced cooling systems tailored for high-heat areas.

4. Energy Optimization

- Variable Frequency Drives (VFDs) for fans and pumps to optimize power usage.

- Heat recovery systems to repurpose waste heat for facility needs.

5. Monitoring and Automation

- IoT-enabled sensors for real-time monitoring of temperature, humidity, and air quality.

- Automated alerts and predictive maintenance to prevent downtime.

Challenges in Semiconductor HVAC Systems

1. High Heat Loads

Semiconductor equipment generates significant heat, requiring robust cooling solutions to maintain stable conditions.

2. Stringent Cleanroom Standards

Achieving and maintaining ISO 14644 cleanliness levels demands continuous filtration and airflow management.

3. Energy Consumption

Balancing performance with energy efficiency is a constant challenge, given the continuous operation of facilities.

4. Chemical Contaminants

Manufacturing processes often release chemicals that can degrade air quality and damage equipment if not effectively removed.

How Atmax Filtration Supports Semiconductor HVAC Needs

1. Tailored Solutions

Atmax Filtration offers customized HVAC systems designed to meet the unique requirements of semiconductor cleanrooms and production areas.

2. Advanced Filtration Technology

Our systems integrate HEPA, ULPA, and gas-phase filtration for superior air quality.

3. Energy-Efficient Designs

We prioritize energy-efficient components and systems, helping clients reduce operational costs and achieve sustainability goals.

4. Comprehensive Support

From system design and installation to maintenance and upgrades, Atmax Filtration provides end-to-end HVAC solutions for semiconductor facilities.

5. Real-Time Monitoring

Our IoT-enabled systems offer real-time data analytics and alerts, ensuring optimal performance and minimal downtime.

Semiconductor manufacturing demands unparalleled precision and control, making specialized HVAC systems an essential investment. By focusing on advanced filtration, precise temperature and humidity regulation, and energy efficiency, these systems help ensure product quality, operational efficiency, and compliance with industry standards.

Atmax Filtration is committed to providing industry-leading HVAC solutions tailored to the semiconductor sector. Contact us today to learn more about how we can enhance your manufacturing environment.